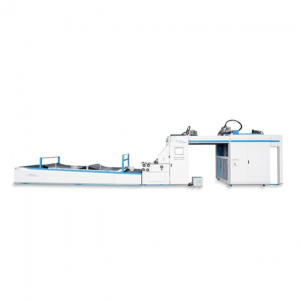

JB-780 e nang le JB-800UVJ UV Dryer le JB-800S Stacker

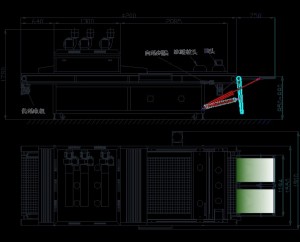

| JB-780 | |

| Boholo ba pampiri | 780×540㎜² |

| Boholo ba pampiri e nyane | 350×270㎜² |

| Boholo ba sebaka sa khatiso | 780×520㎜² |

| Boholo ba foreimi ea skrine | 940×940㎜² |

| Boima ba pampiri | 108-350 g /㎡ |

| Karolo ea pampiri | ≤13㎜ |

| Ho nepahala ha mongolo o fetelletseng | ≤0.10㎜ |

| Bophahamo ba qubu | 700㎜ |

| Lebelo la ho hatisa | 1000-3300 likhomphutha / h |

| Matla | 3P 380V 7.00KW |

| Boima bo felletseng | 3300㎏ |

| Boemo ka kakaretso | 4280×2080×1270㎜³ |

1. Classical swing cylinder sebopeho se nang le ts'ebetso e tsitsitseng le e nepahetseng. Ho sa le joalo, photocell e hlophisitsoe ka mahlakoreng ka bobeli ho lemoha boemo ba mokhoa oa khatiso ho fokotsa litšila tsa khatiso ka katleho.

2. Ho lumellana ho phahameng le taba ea khatiso ea botenya bo fapaneng ho etsa bonnete ba ho matha hantle ka lebelo le phahameng. Feeder ea pampiri e le 'ngoe e ka pele kapa ea stream feeder e ka fetoloa. Moqomo oa pampiri o habeli o khona ho sebelisoa ho phahamisa katleho.

3. Hammoho le sebopeho sa pampiri le ho hatella, tafole ea phepelo e na le lipalangoang tse boreleli tsa mefuta eohle ea thepa.

4. Mechanical sheet sheet le detector ea sheet e se nang letho karolong ea infeeding.

5. Skrine sa moea le ho notlela foreimi e kholo

6. Foreimi ea marang-rang e ntse e sebetsa haufi le seporo sa linear guide e tsoang kantle ho naha le bolo ho fokotsa lerata le ho thothomela ka lebelo le phahameng ho netefatsa botsitso ba khatiso.

7. Lera la lehlakoreng le letšehali le le letona le ka ho sa feleng le ka fetohang ho tsoa ka ntle.

8. Outfeeding tafole fallela holimo le tlaase ka pneumatic cylinder.

9. Mochini oohle o sebelisa mokhoa oa ho lubrication oa auto-lubrication ho etsa bophelo ba mochine nako e telele.

10. Inverter e tsoang kantle ho naha, PLC le likarolo tse ling tse tsebahalang tsa motlakase oa mofuta, moralo oohle oa mochini o lumellana le maemo a CE.

11. Likarolo tse ka sehloohong tsa mochine li hahiloe ke lisebelisoa tsa tlhahiso ea CNC ho netefatsa ho sebetsa ka ho nepahala.

JB-800UVJW e etselitsoe ka ho khetheha hore e sebelisoe ka skrine e iketsang

mochini oa khatiso, mochini oa offset le lisebelisoa tse ling. E sebelisoa haholo

bakeng sa ho shoa, ho tlosa mongobo le ho phekola UV joalo-joalo sebakeng sa skrine

khatiso, khatiso le dae, electroplating, electronic circuit board le

joalo-joalo.

| JB-800UVJW | |

| Fetisa lebelo | 60m/min |

| Matla a lebone la UV | 10 KW×3pcsX mofuta o se nang mohato |

| Matla a lebone a sosobaneng | 80W×3pcs×2 boemo |

| Ho futhumatsa IR bakeng sa matla a boreleli a enke | 1.5 KW×3pc |

| Bophara ba ho phekola | 1100 limilimithara |

| Fetisa matla a motlakase | 400 W |

| Matla a fan ea adsorption | 2.2 KW |

| Felisa matla a fene | 0.37 KW ×3 |

| Feni e nyane | 40 W×13pcs |

| Kakaretso ea matla | 380V 50Hz 95A |

| Kakaretso ea Boima | 1200 Kg |

| Boholo ka kakaretso (L*W*H) | (4.2 + 0,75) × 1,91×1,78 m |

1. Lihlopha tse tharo tsa mohloli oa leseli o laolang ntle le mehato, taolo e ikemetseng, sesebelisoa sa digital se bontšang nako ea sebele ea boemo ba ho sebetsa le bophelo ba tšebeletso.

2. Amohela lebone le khethehileng la aluminium magnesium alloy lampshade, ho tsepamisa mohopolo, katleho e phahameng ea tlhahiso.

3.E na le mokhoa o utloahalang oa ho pholile, lihlopha tse peli tsa mocheso o ikemetseng oa lampshade, karolo e ka tlaase ea tsamaiso ea adsorption, ho thibela mocheso oa kamore ea mosebetsi o phahame haholo, o fella ka deformation ea substrate.

4. Sistimi ea tokiso ea lebanta la conveyor e nang le sistimi ea adsorption, e bonolo ho e sebelisa, e loketseng ho tsamaisa pampiri; Teflon e tsoang kantle ho naha (TEFION) lebanta la mesh, ho hanyetsa mocheso o phahameng, ho hanyetsa likhohlano, tšebeliso e tsitsitseng ho netefatsa nako e telele.

5. Taolo ea lebelo la conveyor e se nang mohato, phetoho ea tlhahiso ea pono, lebelo la ho tsamaisa, ho fihla ho 60 metres / min.

Melemo ea mohloli oa leseli o sa fetoheng ha o bapisoa le mohloli o tloaelehileng oa leseli o laoloang ke transformer ea UV:

Phatlalatso e pharalletseng ea matla: matla a hlahisoang ke tube ea lebone ke 30% ho isa ho 100%, e sa fetoheng;

Sekhahla se phahameng sa ho fetola matla: hoo e ka bang 20% e phahameng ho feta motlakase oa motlakase oa setso oa UV, 'me o ka lelefatsa bophelo ba lebone ka katleho;

Ts'ebetso e phahameng, ho boloka matla le ts'ireletso ea tikoloho: ho fokotsa ka katleho tahlehelo le matla a sebetsang a li-transformer tsa setso, boloka hoo e ka bang 40% ea tšebeliso ea matla ha e bapisoa le selemo se le seng;

Ts'ireletso e bohlale e felletseng: mochini o fetang 20 oa ts'ireletso ea litsebi, joalo ka ho futhumatsa ha tube, phoso ea paramente ea lebone la lebone, ho khaoha ha lebone la lebone, joalo-joalo;

matla a ho ikamahanya le maemo a phahameng a bohlale: litlhophiso tsa standby, ha ho na lintho tse kenyelelitsoeng, 30% matla a standby; thepa e ka, ka hare ho 0.5 metsotsoana ka tsela e iketsang ho beha matla;

Tšebeliso e phethahetseng ea ts'ireletso: qoba ho futhumatsa motlakase oa setso le mochini oa wiring o bakoang ke likotsi tsa ts'ireletso.

| JB-800S | |

| Max. Boholo ba pampiri | 800×540㎜² |

| Min. Boholo ba pampiri | 350×270㎜² |

| Max. Bophahamo ba qubu | 700㎜ |

| Lebelo le holimo | 3600sheet/h |

| Matla a kentsoeng | 3P 380V 50Hz 1.32KW |

| Boima bo felletseng | 650㎏ |

| Boholo ka kakaretso | 1500×1800×1000㎜³ |

1. Mochine oohle o laoloa ke PLC, o bokella substrate ea khatiso le ho etsa pampiri ka tatellano ka ho toba.

2. Tlhokomelo ea motlakase oa lifoto, mahlakore a mabeli a li-baffle a matha ha pampiri e kena poleiti.

3. Sistimi ea ho tsamaisa pampiri e laoloa ke inverter e nang le taolo ea lebelo le se nang mohato le lebanta la conveyor le tataisa lebili le sa sebetseng ho fepa pampiri.

4. Lintho tsa moea li laola ketso ea jogger, e qobang hore pampiri e robehe kapa tšenyo e 'ngoe.

5. Ho latela mefuta eohle ea boholo ba pampiri, sesebelisoa sa ho matha ka pampiri se ka fetoloa ho tloha ka morao, ka ho le letšehali le ka ho le letona habonolo le ka mokhoa o bonolo.

6. Sensor induction etsa hore stacking boto fatše ka tsela e iketsang 'me u boloke pampiri bokella hantle.

7. Pampiri ea stacker e na le mokhoa o fokolang oa tšireletso sebakeng sa holimo le tlase ho qoba mochine hore o senyehe.

8. Tlhokomelo ea bophahamo ba qubu ea pampiri le qubu ea pampiri le ho etsa hore mochine oa khatiso o eme moleng.

9. E hokahane le karolo ea khatiso e ka laolang ho sebetsa ha karolo ea khatiso.

10. Mosebetsi oa ho bala pampiri.