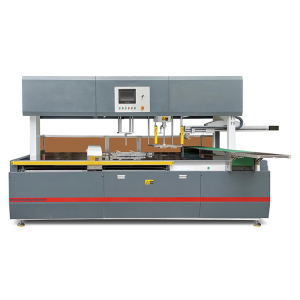

HTQF-1080CTR Automatic Strip with Double Heads Blanking Machine bakeng sa lebokose

1. Ho ntša lihlahisoa tse feliloeng ka mor'a mokhoa oa ho itšeha, bakeng sa ho tlosa litšila.

2. E sebelisoa bakeng sa lihlahisoa tse ngata tse khaotsoeng tse kang li-labels, li-hang tags, likarete tsa khoebo, mabokose a limpho, mabokose a lijo, linoelo tsa pampiri le lihlahisoa tse ling tsa ho seha ka pampiri kapa polasetiki, letlalo la PU.

3. Lihlooho tse peli tsa mosebetsi: ho hloekisa lesoba le ka hare + hlooho e le 'ngoe e hlobolang

4. Rotary hlooho ea ho hlobolisa ho ntša ka lehlakoreng le fapaneng shoa ho itšeha lihlahisoa habonolo.

5.Ho ntša sehlahisoa ka bohona ka letsoho la manipulator le ho beha sehlahisoa holim'a lebanta la thomello.

6. PLC e laoloang ka bohlale le ts'ebetso e bonolo.

7. Automatic lubrication system bakeng sa tlhokomelo e ntlafetseng ea mochine.

8. Libopeho tse fapaneng li ka etsoa ka mokhoa o tloaelehileng e le tlhokahalo ea bareki.

| Mohlala | HTQF-920CTR | Tlhaloso: HTQF-1080CTR |

| Boholo ba Mochini | L4200xW2250xH2020 | L4290xW2490xH2020 |

| Boholo ba lakane (X x Y) mm | 920 x 680 | 1080 x 780 |

| Saese e nyane ya lakane (X x Y) mm | 550 x 400 | 650 x 450 |

| Bophahamo bo phahameng ba qubu / mm | 100 | 100 |

| Bophahamo bo fokolang ba qubu / mm | 40 | 40 |

| Bophahamo ba tafole ea mosebetsi mm | 850 | 850 |

| Boholo ba sehlahisoa bo tlameha ho hlakisoa | 420 x 420 | 390 x 390 |

| Min. boholo ba sehlahisoa se lokelang ho phunngoa | 30*30 | 30*30 |

| Linako tsa lebelo la ho hlobola/metsotso | 15-22 | 15-22 |

| Max. matla (bar) | 70 | 70 |

| Tšebeliso ea moea L/min | 3 | 3 |

| Manipulator Grip Range /mm | 30-260 limilimithara | 30-300 limilimithara |

| Manipulator Grip Weight | 50-1500 g | 50-1800 g |

| Matla a Matla | 5kw 380V | 5kw 380V |

| Boima bo kahare | 2.9T | 3.2T |

| Boholo ba Sephutheloana | 3700x1900x2200 | |

| Boima bo felletseng | 2.5T | 3T |

| Boima bo felletseng | 3.6T | 4.0T |

1. Ho ntša sehlahisoa se felileng ka mor'a mokhoa oa ho itšeha, bakeng sa ho tlosa litšila.

2. E sebelisoa bakeng sa lihlahisoa tse ngata tse sehiloeng tse kang li-label, li-hang tags, likarete tsa khoebo, lebokose la limpho, lebokose la lijo, linoelo tsa pampiri le lihlahisoa tse ling tsa ho seha ka pampiri kapa polasetiki, letlalo la PU.

3. PLC e laoloang ka bohlale le ts'ebetso e bonolo.

4. Automatic lubrication system bakeng sa tlhokomelo e ntlafetseng ea mochine.

5. Lihlahisoa tse fapaneng tsa sebopeho li ka etsoa ka tloaelo e le tlhokahalo ea bareki.

Sistimi e fetolehang ea hydraulic

Lekhoakhoa la tšireletso

Sistimi e bohareng ea lubrication

Sekala sa pampiri se nang le enjene e patiloeng le screw ea bolo