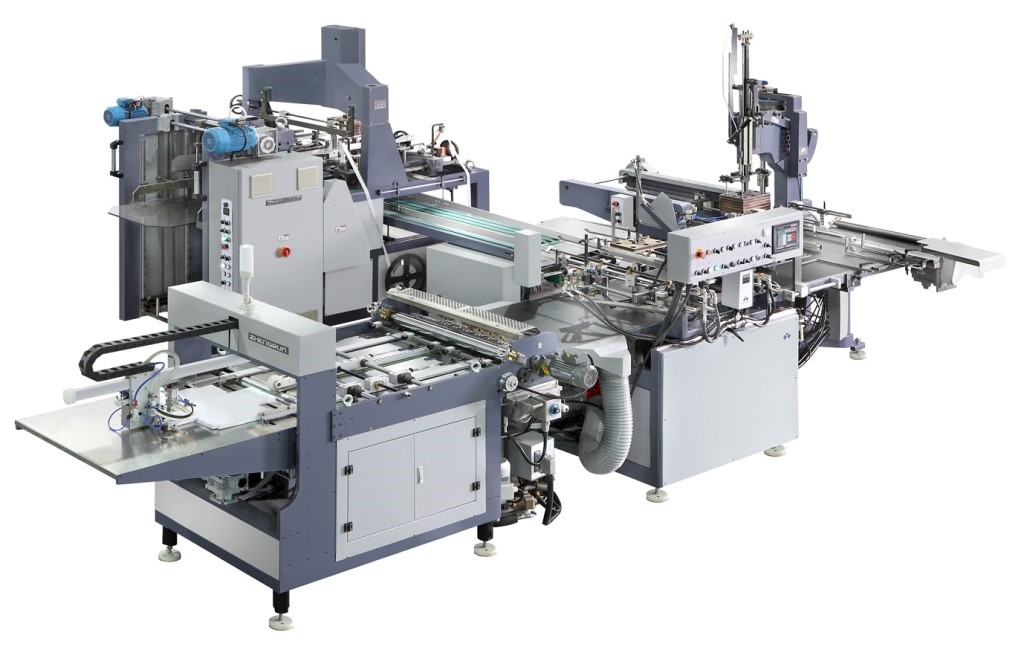

RB420 Automatic Rigid Box Maker

| Mohlala | RB420 | |

| 1 | Boholo ba pampiri(A×B) | Min.100×200mm |

| Max.580×800mm | ||

| 2 | Boholo ba lebokose(W×L) | Min. 50 × 100 limilimithara |

| Max.320×420mm | ||

| 3 | Botenya ba pampiri | 100-200g/m2 |

| 4 | Botenya ba kareteboard(T) | 1-3 limilimithara |

| 5 | Bophahamo ba lebokose(H) | 12-120 limilimithara |

| 6 | Boholo ba pampiri e menaneng(R) | 10-35 limilimithara |

| 7 | Nepahalo | ± 0.50 limilimithara |

| 8 | Lebelo | ≦28sheets/min |

| 9 | Matla a motlakase | 11.8kw/380v 3mohato |

| 10 | Matla a heater | 6kw |

| 11 | Boima ba mochini | 4500kg |

| 12 | Boholo ba mochini(L×W×H) | L6600×W4100×H 2500mm |

1. Boholo le boholo bo nyane ba mabokose bo tlas'a tsa pampiri le boleng ba pampiri.

2. Lebelo la mochine le itšetlehile ka boholo ba mabokose.

3. Ha re fane ka compressor ea moea.

Likamano tse tšoanang pakeng tsa parameter:

W+2H-4T≤C(Max) L+2H-4T≤D(Boholo)

A(Min)≤W+2H+2T+2R≤A(Max) B(Min)≤L+2H+2T+2R≤B(Max)

1. Mofani oa mochine ona o amohela mokhoa oa ho fepa ka morao-push, o laoloang ka pneumatically, 'me sebopeho sa oona se bonolo ebile se utloahala.

2. Bophara pakeng tsa stacker le tafoleng ea ho fepa e fetoloa concentrically bohareng. Opereishene e bonolo haholo ntle le mamello.

3. Sekoti se secha se entsoeng ka koporo se sebelisana le rolara ka mokhoa o tsitsitseng haholoanyane, ka katleho ho qoba ho phunya pampiri. 'Me scraper ea koporo e tšoarella ho feta.

4. Adopt imported ultrasonic double paper tester, e nang le tshebetso e bonolo, e ka thibelang likotoana tse peli tsa pampiri ho kena mochine ka nako e le 'ngoe.

5. Ho potoloha ka mokhoa o itekanetseng, ho kopanya le tsamaiso ea gluing bakeng sa sekhomaretsi se chesang se chesang. (Sesebelisoa sa boikhethelo: mitha ea viscosity ea glue)

6. Theipi ea pampiri e qhibilihang e chesang e fetisang, e sehang, 'me e qetelle e khomaretse lebokose le ka hare la quad stayer (li-angles tse 'nè) tsa khateboto ka mokhoa o le mong.

7. Fene e hulang ka vacuum tlas'a lebanta la conveyer e ka etsa hore pampiri e se ke ea kheloha.

8. Lebokose le ka hare la pampiri le khateboto le sebelisa sesebelisoa sa hydraulic rectifying ho bona hantle.

9. Sephutheloana se ka lula se phuthela, sa phutha litsebe le mahlakoreng a pampiri 'me sa theha ka mokhoa o le mong.

10. Mochine oohle o sebelisa PLC, tsamaiso ea ho latela photoelectric le HMI ho iketsetsa mabokose ka mokhoa o le mong.

11. E ka hlahloba mathata le alamo ka tsela e nepahetseng.