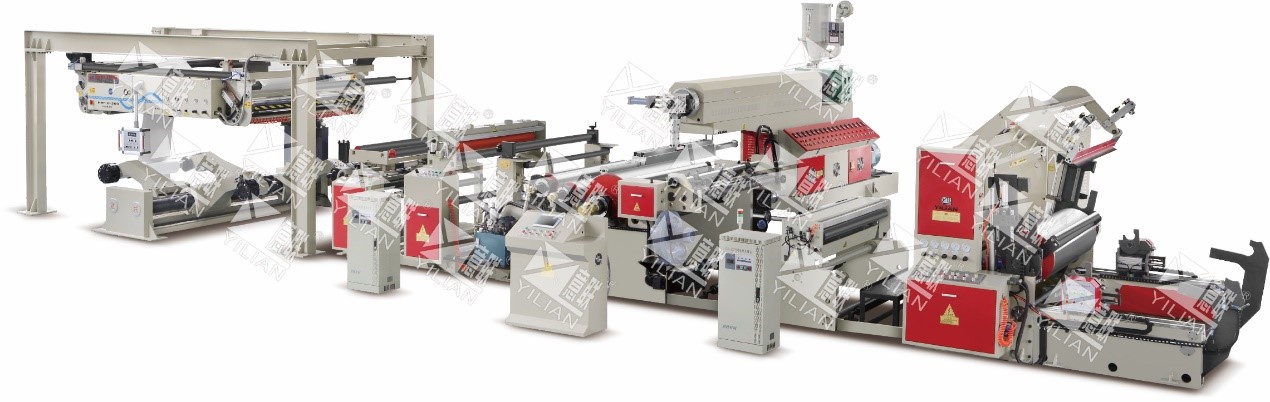

WSFM1300C Automatic Paper PE Extrusion Coating Machine

| Sutu laminating resin | LDPE, PP joalo-joalo |

| Sutu thepa ea motheo | pampiri (80-400g/m²) |

| Lebelo le phahameng la mochini | 300m / min (lebelo la ho sebetsa le ipapisitse le botenya ba ho roala, bophara) |

| Bophara ba ho roala | 600-1200, bophara ba rolara: 1300mm |

| Botenya ba ho roala | 0.008—0.05mm (Sekurufu se le seng) |

| Phoso ea botenya ba ho koahela | ≤±5% |

| Boemo ba maemo a khatello ea maikutlo | 3-100kg ka botlalo |

| Boholo ba extruder bongata | 250 kg/h |

| Motsoako pholileng rolara | ∅800×1300 |

| Screw Diameter | ∅110mm karo-karolelano ea 35:1 |

| Bophahamo bo phahameng ba ho phutholoha | ∅1600 limilimithara |

| Bophara ba ho khutlisa morao | ∅1600 limilimithara |

| Unwind pampiri konokono dia :3 ″6 ″ le Rewind pampiri konokono bophara bophara: 3 ″6 ″ | |

| Extruder e tsamaisoa ke 45kw | |

| Kakaretso ea matla | hoo e ka bang 200 Kw |

| Boima ba mochini | hoo e ka bang 39000kg |

| Boemo bo ka ntle | 16110 limilimithara×10500 limilimithara ×3800 limilimithara |

| 'Mala oa' mele oa mochini | Bohlooho le Bokhubelu |

1. Unwind karolo (ka PLC, servo unwinding)

1.1 Fokotsa foreime

Sebopeho: Foreimi e sa phutholohang ea shaft ea Hydraulic

The BA series splicer e etsa karolo ea bohlokoa ea mola oa lamination mme e kentsoe holim'a sethala sa roll ka tlas'a sebopeho sa borokho.E lumella ho tsoela pele ho sebetsa ha moqolo o teng oa pampiri ho ea moqolong o latelang oa pampiri ntle le ho emisa tlhahiso.

Ka har'a liforeimi tsa mahlakoreng a splicer ho na le lihlooho tse 2 tse tsamaisanang le karolo ea tšehetso e bohareng.Ka holim'a eona ho na le li-nip rolls tse 2.

Capstan roll, reverse idler roll le double dancer system li theha karolo ea ho bokella pampiri e khonang ho bokella pampiri ho fihlela makhetlo a 4 bolelele ba splicer.

Mochine o sebetsoa ka phanele ea ts'ebetso mochining

Lebelo la ho kopanya pampiri Max.300m/min

a) ha matla a pampiri a ka holimo ho 0.45KG/mm, max.300m/min;

b) ha matla a pampiri a ka holimo ho 0.4KG/mm, max.250m/min;

c) ha matla a pampiri a ka holimo ho 0.35KG/mm, max.150m/min;

Bophara ba pampiri

Max.1200 limilimithara

Min.500 limilimithara

Lebelo CE-300

Max.300m/min

Lintlha tsa moea

Beha khatello ea 6.5 bar

Min.khatello ea 6 bar

Mohlala oa CE-300

Matla a 3.2kVA, 380VAC/50Hz/20A

Matla a ho laola 12VDC/24VDC

1.1.1 Mofuta o ikemetseng oa hydraulic shaft spindle clamp arm mofuta oa seteishene sa ho sebetsa habeli, ntle le shaft ea moea, ho kenya hydraulic, boloka litšenyehelo tsa ho kenya sebopeho sa mochini.Phetoho e iketsang ea AB shaft auto reel, tšenyo e nyane ea thepa.

1.1.2 Max.Sehlahisoa sa ho bula: ¢1600mm

1.1.3 Auto tension setting range : 3-70kg margin e feletseng

1.1.4 tsitsipano ho nepahala: ± 0.2kg

1.1.5 mokokotlo oa pampiri: 3" 6"

1.1.6 Sistimi ea taolo ea tsitsipano: mofuta oa shaft oa detector ea tsitsipano ka mokhoa o nepahetseng oa ho lemoha potentiometer, taolo e bohareng ea programmable PLC.

1.1.7 Sistimi ea taolo ea koloi: PIH cylinder braking, karabo ea rotary encoder ka potlako, khatello e nepahetseng ea khatello ea valve e koetsoeng, taolo e hlophisitsoeng ea PLC.

1.1.8 Tension setting :Ka mokhoa o nepahetseng oa ho laola khatello ea li-valve

1.2 Ho boloka mofuta oa ho khetha ka boiketsetso, sesebelisoa sa ho itšeha

1.2.1 Ho boloka ho tsamaisoa ke buffer ea koloi ea moea, ho netefatsa tsitsipano e tsitsitseng ha u khetha pampiri.

1.2.2 sebopeho se arohaneng sa ho itšeha

1.2.3 PLC e bala lebelo le lecha la rotary, 'me u boloke lebelo ka lebelo la mohala oa mantlha

1.2.4 Amohela rolara ea khatiso ea lintho tse bonahalang, seha se seha thepa e robehileng .tension control change, reset all can finish in automatically

1.2.5 phetoho ea pele ea alamo,: bophara ba mosebetsi ha bo fihla 150mm., mochini o tla alamo

1.3 Taolo ea ho lokisa: sisteme ea taolo ea ho lokisa ea photoelectric putter (bst structure)

2. Corona (Yilian customized)

Matla a kalafo ea Corona: 20 kw

3. Yuniti ea lamination ea Hydraulic:

3.1 Three rollers laminating motsoako sebopeho, ka morao tobetsa rolara, ka etsa motsoako rolara bere matla esita le, kompone tiileng.

3.2 Ho tlosoa ha silicon rabara rolara: sehlahisoa se kopantsoeng se bonolo ho se sheba ho tloha ho rolara e pholileng, Hydraulic e ka hatella ka thata.

3.3 The kobehileng moqolo filimi flattening sebopeho,: ka etsa hore filimi ka potlako ho romelwa

3.4 Compound feed material adjust roller e ka hlola botenya ba thepa ea lifilimi bo sa lekaneng joalo-joalo bofokoli

3.5 Mofuthu o matla o monya sekhechana ka potlako.

3.6 Motsoako oa seha sehang

3.7 Compound roller e khannoa ka motlakase

3.8 Compound roller driven motor e laoloa ke Japan frequency controller

Tlhaloso:

(1) rolara ea motsoako:¢ 800 × 1300mm 1pcs

(2) rolara ea rabara:¢ 260 × 1300mm 1pcs

(3) tobetsa rolara:¢ 300 × 1300 limilimithara 1pcs

(4) moqomo o kopanyang oa oli:¢63 × 150 2pcs

(5) ebola rolara:¢130 × 1300 1pcs

(6) 11KWmotor (SHANGHAI) 1set

(7) 11KW Frequency converter (JAPAN YASKAWA)

(8) potoloha sehokelo: (2.5"2 1.25"4)

4. Extruder (ho lokisa bophahamo ba koloi)

4.1 Screw bophara:¢ 110, Max extruder hoo e ka bang: 250kg/h (theknoloji ea Japane)

4.2 T-die (Taiwan GMA)

4.2.1 Bophara ba hlobo: 1400mm

4.2.2 Mold ka bophara bophara: 500-1200mm

4.2.3 Lekhalo la molomo oa hlobo: 0.8mm, botenya ba ho roala: 0.008—0.05mm

4.2.4 Phoso ea botenya ba ho koahela: ≤± 5%

4.2.5 Motlakase o futhumatsang tube ka hare ho futhumatsang, ho futhumatsa ka katleho e phahameng, mocheso o eketseha ka potlako

4.2.6 Phaseje e kentsoeng ka ho feletseng, Tokiso ea bophara ba Stuffing

4.3 Lisebelisoa tsa marang-rang tse fetolang ka potlako

4.4 Ho tsamaea ka pele le ka morao, ho ka phahamisa Trolley ka bo eona, ho phahamisa mefuta: 0-100mm

4.5 Mold 7 libaka taolo ea mocheso.Screw barrel 8 karolo ea taolo ea mocheso.sehokelo 2 sebaka taolo ea mocheso e amohela Infrared futhumatsang diyuniti.

4.6 Lebokose le leholo la ho fokotsa matla a ho fokotsa matla, LENO LE HARD (Guo tai guo mao)

4.7 Taolo ea mocheso oa Digital mocheso o itekanetseng

Likarolo tse kholo:

(1) 45kw AC motor (SHANGHAI)

(2) 45KW frequency converter (JAPAN YASKAWA)

(3) Digital mocheso molaoli 18pcs

(4) 1.5KW motlakase o tsamaeang

5.Pneumatic Round thipa ho kuta sesebelisoa

5.1 Trapezoidal screw transverse adjusting device, fetola bophara ba pampiri

5.2 Pneumatic Pressure cutter

5.3 5.5kw khatello e phahameng bohale monya

6.Rewinding Unit : 3D boima mosebetsi sebopeho

6.1 Moralo o khutlisang morao:

6.1.1 Mochini o khutlisang motlakase oa mofuta oa friction habeli, ho itšeha ka lebelo le phahameng le ho khetha thepa e felileng, ho laolla ka boiketsetso.

6.1.2 Max.ho khutlisa bophara:¢ 1600 mm

6.1.3 lebelo la ho phalla: 1r / min

6.1.4 tsitsipano: 3-70kg

6.1.5 Tension ho nepahala: ± 0.2kg

6.1.6 konokono ea pampiri: 3" 6 ″

6.1.7 Sistimi ea Taolo ea Tension: Moqomo o phaphametse sebopeho sa mofuta oa rolara e phaphametseng, tsitsipano e bonoa ke potentiometer e nepahetseng, 'me molaoli ea hlophisitsoeng oa PLC o laola tsitsipano bohareng.(Japan SMC low friction cylinder) 1 sete

6.1.8 Drive Control System: 11KW motor drive, rotary encoder speed feedback, Senlan AC inverter dual closed-loop control, programmable controller PLC centralized control.1 sete

6.1.9 Tlhophiso ea Khatello e Tsoelang Pele: Setlhophiso sa Precision Pressure Regulator (Japan SMC)

6.0.1

6.2 Sesebelisoa sa ho Fepa le ho Seha ka Boiketsetso

6.2.1 Splicing Support Rollers e laoloa ke PLC ho khanna koloi ho tšoara thepa hole le rolara ea rubbing.

6.2.2 Mokhoa oa ho Seha o Ikemetseng oa Hydraulic

6.2.3 PLC palo ea othomathike ea ts'ebetso ea ho khetha, ho nkeloa sebaka ha molumo ho phetheloa ka senotlolo.

6.2.4 Mosebetsi oa Rolara e Tšehetsang, Lisebelisoa tsa ho Seha, Seta bocha, joalo-joalo. E phethetsoe ka ho iketsa

6.2.5 Litlhaloso

(1) friction roller: ¢ 700x1300mm 1 bar

(2) Enjene e tsamaisang moea: 11KW (Shanghai Lichao) sete e le 'ngoe

3

(4) Inverter: 11KW (Japan Yaskawa) 1 sete

(5) Lebokose la lisebelisoa tsa li-roller: 1 sete ea matla

(6) Speed reducer: leino le thata 1 sete ea matla

(7) Ho fokotsa lebelo la ho tsamaea: 1 sete ea matla

(8) Ho lahla seteishene sa hydraulic

7.Auto air shaft puller

8.Drive Karolo

8.1 Enjene e kholo, lebanta la phetiso le nka lebanta la synchronous

8.2 Enjene e kopanyang, e khutlisetsang morao le e thellang: Lebanta la ho khanna le nka lisebelisoa tsa arc, ketane le phetisetso ea lebanta le lumellanang

8.3 Lebokose la lisebelisoa tse ka sehloohong tsa koloi: Ho tiisa lisebelisoa tsa helical tse qoelitsoeng ka oli, sebopeho sa phetisetso ea li-helical gear

9.Setsi sa Taolo

Khabinete e ikemetseng ea motlakase, taolo e bohareng, sebaka se kopaneng se nang le ts'ebetso ea khabinete ea taolo e bohareng.Sistimi ea othomathike ea mochini e sebelisang sesebelisoa sa PLC (hollsys) se nang le bokhoni bo phahameng ba ho sebetsa, le matšoao a puisano a mochini oa motho a sebelisa puisano ea marang-rang lipakeng tsa sebopeho.PLC, yuniti ea extrusion, puisano ea mochini oa motho lipakeng tsa sistimi ea ho khanna mme e theha sistimi e kopaneng ea taolo e ikemetseng.Bakeng sa paramethara efe kapa efe ka seta, ka palo othomathike, memori, lemoha, alamo, joalo-joalo Na tsitsipano ya bonwang pontšo sesebediswa, lebelo, barbotage botenya, lebelo le fapaneng boemo sebetsa.

10. ba bang

11.1 Tataiso ea Roller: Anodization e thata ea aluminium alloy roll roll, ts'ebetso ea motsamao

11.2 Lisebelisoa tse tlase tsa motlakase bakeng sa France Schneider, omron Japan, joalo-joalo.

11.parts brand

11.1 PLC (Beijing Hollysys)

11.2 Skrine sa ho ama (TAIWAN)

11.3 frequency converter: Japan Yaskawa

11.4 Enjene e kholo: SHANGHAI

11.5 silindara e tlase ea likhohlano (Japan SMC)

11.6 AC CONTACTOR (Schneider)

11.7 konopo (Schneider)

11. Motsoako o tsitsitseng (Taiwan)

11.9 valve e laolang khatello ea silinda (Taiwan)

11.10 Valofo ea phapanyetsano ea Magnetic (Taiwan)

11.11 valve e laolang khatello e nepahetseng (SMC)

12.Customer self e fana ka lisebelisoa

12.1 Sebaka sa thepa le motheo

12.2 Phepelo ea lisebelisoa bakeng sa khabinete ea motlakase ea Mochini

12.3 Phepelo ea metsi litsing tsa mochini ho kena le ho tsoa keiting (moreki o lokisa sehatsetsi sa metsi)

12.4 Phepelo ea khase mochining o kenang le ho tsoa ka har'a stomatal

12.5 Phaephe ea ho ntša metsi le fene

12.6 Bokella, laolla le ho laolla thepa ea motheo sesebelisoa se phethiloeng

12.7 Lisebelisoa tse ling tse sa thathamisoang ka konteraka

13. Lenane la likarolo tse ling:

| Che. | Lebitso | Spec. |

| 1 | Thermocouple | 3M/4M/5M |

| 2 | Selaoli sa mocheso | Omron |

| 3 | Micro-regulating valve | 4V210-08 |

| 4 | Micro-regulating valve | 4V310-10 |

| 5 | switjha e haufi | 1750 |

| 6 | Relay e tiileng | 150A le 75A |

| 7 | switjha leeto | 8108 |

| 10 | yuniti e futhumatsang | ϕ90*150mm,700W |

| 11 | yuniti e futhumatsang | ϕ350 * 100mm, 1.7KW |

| 12 | yuniti e futhumatsang | 242 * 218mm, 1.7KW |

| 13 | yuniti e futhumatsang | 218*218mm, 1KW |

| 14 | yuniti e futhumatsang | 218*120mm,800W |

| 15 | konopo ea Schneider | ZB2BWM51C/41C/31C |

| 16 | moea mokoko | |

| 17 | Theipi e phahameng ea mocheso | 50mm*33m |

| 18 | theipi ea telflon | |

| 19 | Corona rolara sekoahelo | 200 * 1300mm |

| 20 | Letlapa la koporo | |

| 21 | sefe ea skrineng | |

| 22 | Potoloha liphahlo | 150*80*2.5 |

| 23 | sehokedi sa moya | |

| 24 | sethunya sa moea | |

| 25 | motsoako oa metsi | 80A le 40A |

| 27 | screws le tse ling | |

| 28 | hula ketane | |

| 29 | lebokose la lisebelisoa |

Likarolo tse kholo le setšoantšo:

Unwinder(Auto splicer) → tataiso ea webo → Corona treater → Extrusion le ho kopanya karolo ea Edge Trimming → Ho khutlisetsa morao